Computational Knitting

2017 Digital Fabrication KnitCreteKnitting offers the possibility to directly create 3D geometries without the need for tailoring or stitching. A two-dimensional line-by-line set of instructions for the CNC-knitting machine to follow during the knitting process, known as a knitting pattern, is needed to fabricate a given piece of weft-knitted textile. Currently, these knitting patterns are designed directly in 2D based on developed surfaces, primitives, or rationalized schemes for non-developable geometries. Any custom, non-repetitive, non-developable knitting pattern needs to be programmed by the user in a manner requiring detailed manipulation and understanding of knitting operations. Creating such patterns is time-consuming and very difficult for geometries not based on known primitives.

In contrast to other industries, such as the garment and shoe or automotive industries, where knitting is used for mass production, the construction sector has a greater demand for non-repetitive modules using bespoke geometries. Therefore, creating knitting patterns for various 3D geometries in a fast and flexible way is especially important.

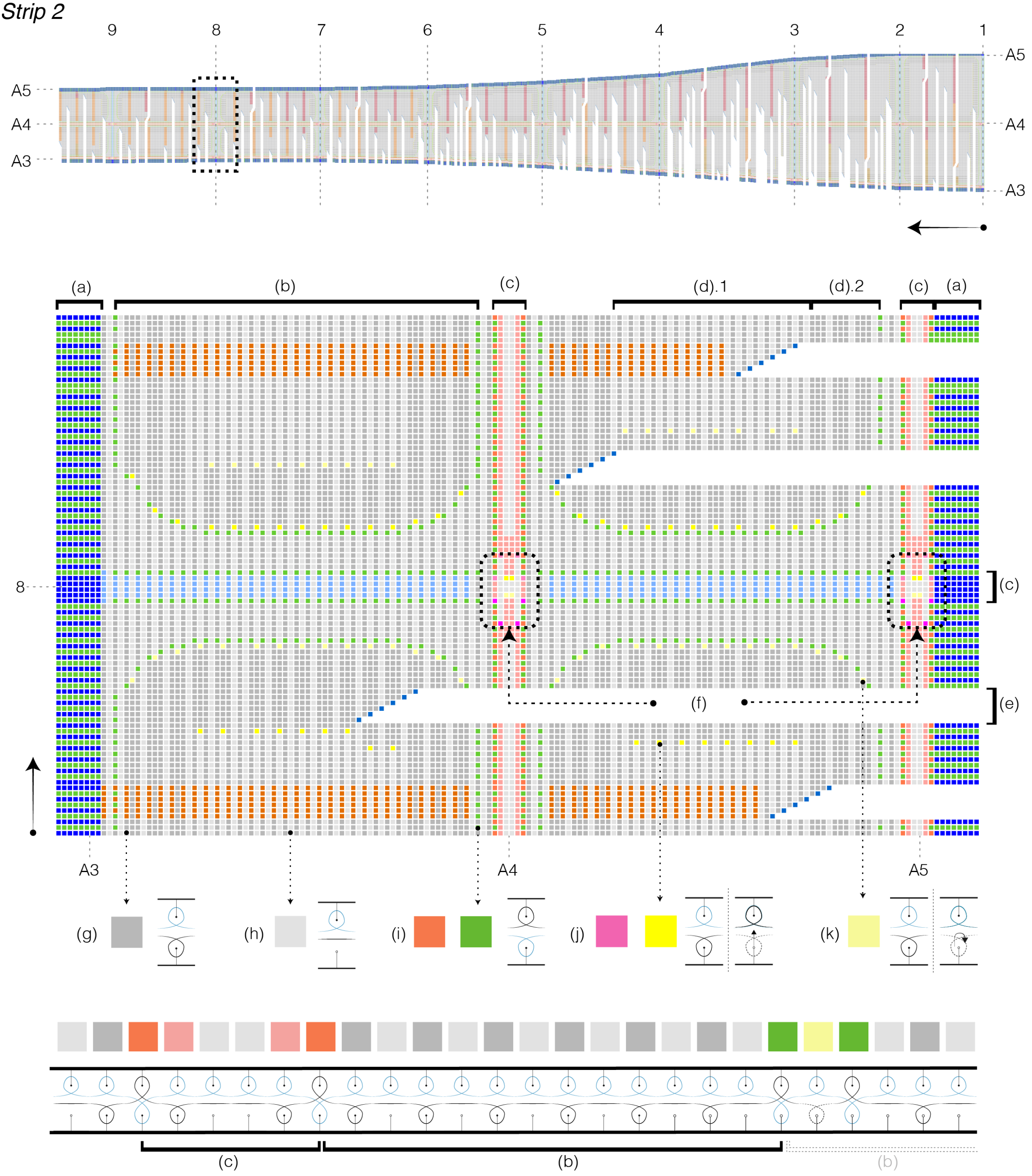

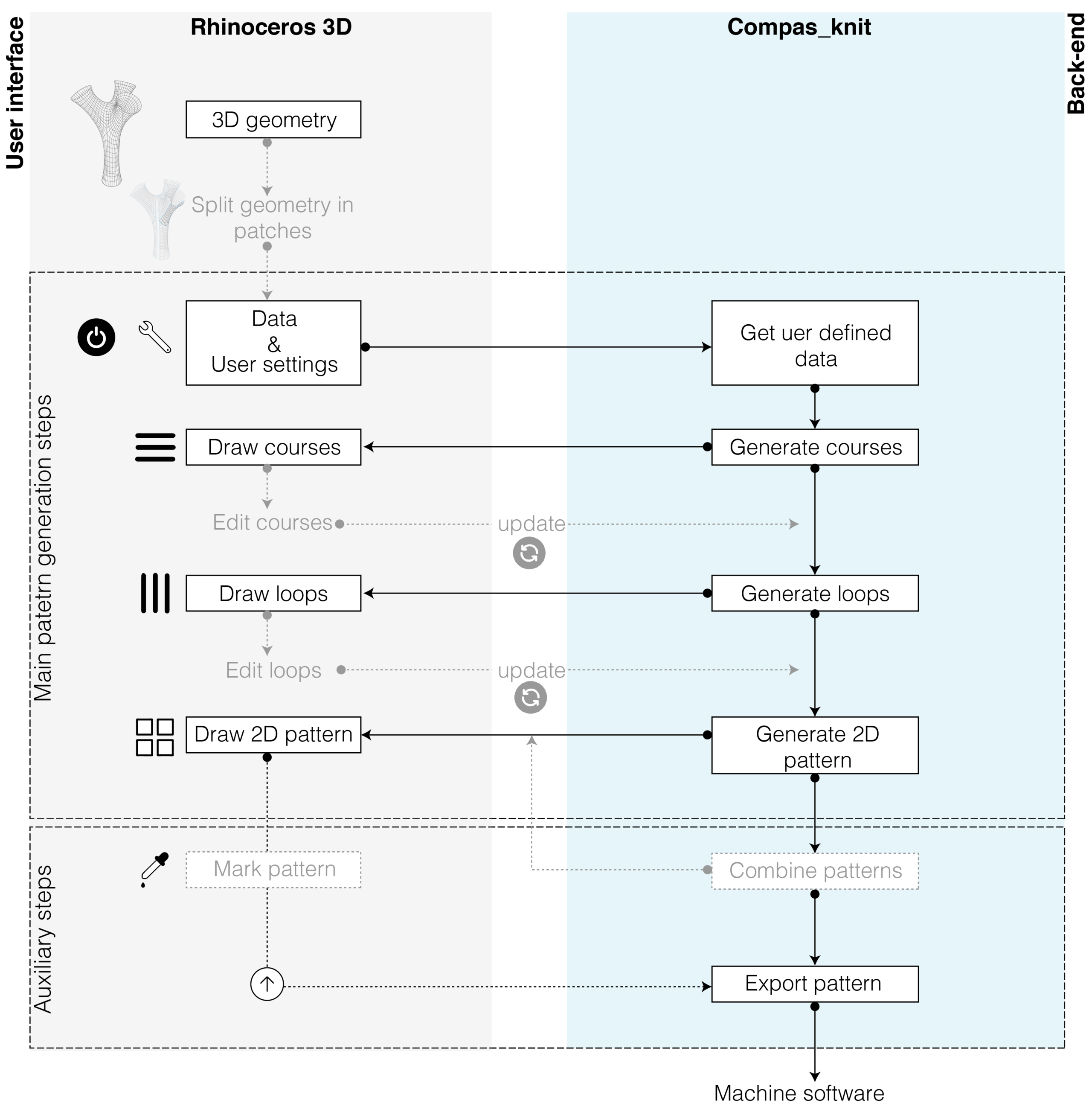

compas_knit is a package developed as an addition to COMPAS, a python-based computational framework for collaboration and research in architecture, structures, and digital fabrication. The package is a pipeline for design to fabrication of knitted textiles consisting of an approach to automatically generate knitting patterns for a given 3D geometry. These patterns are generated as a graph onto a 3D model of the desired shape and represented as a 2D pixel-grid diagram. The 2D patterns include accurate placement of shaping operations such as increases, decreases, and short-rows. The approach is implemented as a design tool in Rhinoceros 3D, giving architects and designers the possibility to set the knitting parameters, choose the knitting direction, manipulate the pattern, and mark features such as channels, openings, or color patterns. Once generated, the patterns are exported as bitmap image files, which can be imported for processing in the knitting machine software.

Compatibility

This approach has been tested and proven to work with three different machine setups:

Steiger – Libra 3.130, with Model 9

Shima Seiki-SWG091N, with SDS-Oneapex

Brother – Electronic KH-970, with img2track

Related publications

Popescu M., Rippmann M., Van Mele T. and Block P. “Automated generation of knit patterns for non-developable surfaces”, Humanizing Digital Reality – Proceedings of the Design Modelling Symposium 2017, K. De Rycke et al. (editors),: 271-284, Springer, Paris, 2017 (September).

Credits

the package and pipeline are a result of my PhD research: “KnitCrete: Stay-in-place knitted fabric formwork for complex concrete structures”