KnitNervi

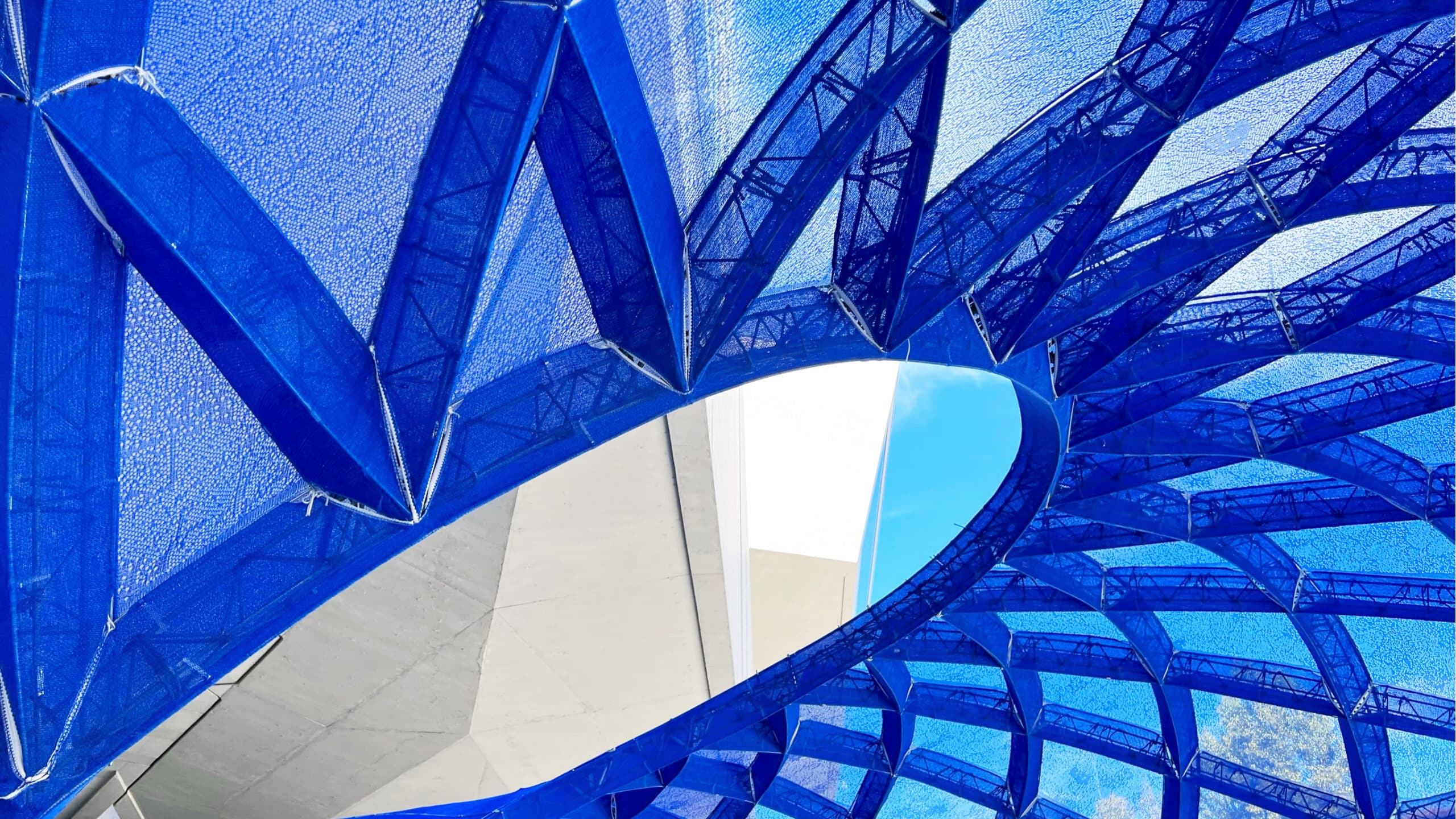

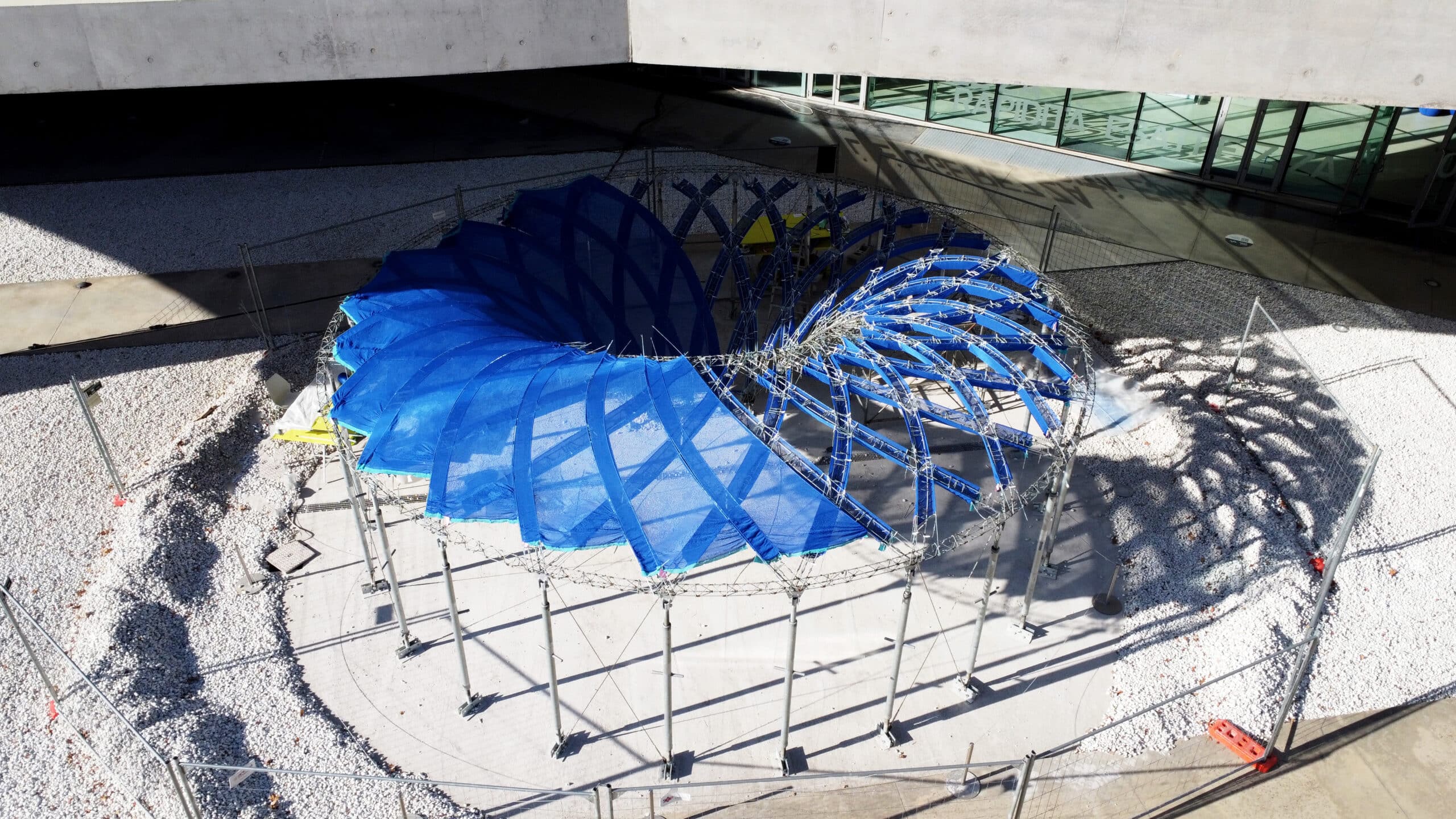

2022 Design Digital Fabrication KnitCrete Research RomeKnitNervi is the pavilion-scale demonstrator of a flexible formwork system for constructing a ribbed concrete shell.

The system consists of a bending-active gridshell, as falsework and reinforcement, encapsulated by a CNC-knitted flexible formwork.

As part of the Technoscape exhibition at the MAXXI Museum in Rome, KnitNervi offers a roadmap for interdisciplinary co-development in architecture, engineering and construction. The ambition is to nurture a conversation on sustainable and structurally-efficient architecture in the XXIst century.

The demonstrator draws inspiration from the pioneering Palazzetto dello Sport by Pier Luigi Nervi to reimagine ribbed, thin-shell, reinforced-concrete construction. The project breaks away from the prefabrication and standardisation paradigms enabling expressive and efficient concrete shells by proposing a construction system without the need for complex, wasteful moulds.

More Info

The installation embodies a flexible formwork system for ribbed reinforced concrete shells. The highly articulated, doubly-curved geometry is form found to act in pure compression with a tension ring at its perimeter. A bending-active gridshell serves as the primary structure of the formwork and simultaneously as the integrated reinforcement of the final concrete shell. KnitCrete, a CNC-knitted flexible stay-in-place shuttering, encapsulates the expressive geometry.

Fact Sheet

- Location: MAXXI – National Museum of 21st Century Art 41.928649060976156N, 12.467783161497518E

- Global dimensions shell: 9.0m x 9.0m x 3.3m

- Covered area: 56.6 m2

- Weight steel reinforcement: 533 kg

- Weight shuttering: 30 kg

- Weight of formwork system: 10.8 kg/m2

- Total length steel splines: 0.7 km

- Type of yarn: Polyester (PES)

- Knitting time: 80 hours

- Number of supports: 29

Publications

Scheder-Bieschin L., Spiekermann K., Popescu M., Bodea S., Van Mele T. and Block P.Design-to-fabrication workflow for bending-active gridshells as stay-in-place falsework and reinforcement for ribbed concrete shell structures,Design Modelling Symposium Berlin 2022 – Conference Proceedings,Springer Fachmedien2022.in press

Related research:

Popescu M., Rippmann M., Liew A., Reiter L., Flatt R.J., Van Mele T. and Block P. “Structural design, digital fabrication and construction of the cable-net and knitted formwork of the KnitCandela concrete shell”, Structures, 2020

Popescu M., Rippmann M., Van Mele T. and Block P. “KnitCandela – Challenging the construction, logistics, waste and economy of concrete-shell formworks”, FABRICATE 2020, London, 2020 (April).

Links

Credits

Short credits

Block Research Group, ETH Zurich (BRG)

Dr. Mariana Popescu – 3MD, TU Delft Faculty of Civil Engineering and Geosciences

Full credits

Design

ETHZ BRG: Lotte Scheder-Bieschin, Serban Bodea, Tom Van Mele, Philippe Block

TU Delft: Mariana Popescu, Nikoletta Christidi

Structural engineering

ETHZ BRG: Lotte Scheder-Bieschin, Philippe Block

Knitted formwork

TU Delft: Mariana Popescu, Nikoletta Christidi

Fabrication and construction

ETHZ BRG:Kerstin Spiekermann, Lotte Scheder-Bieschin, Serban Bodea, with support of Eva Schnewly, Damaris Eschbach, Rolf Imseng, Stefan Liniger

TU Delft: Mariana Popescu, Nikoletta Christidi

Project and site construction coordination

ETHZ BRG: Serban Bodea

TU Delft: Mariana Popescu

Exhibition content, coordination, and curation

Lotte Scheder-Bieschin, Serban Bodea, Mariana Popescu, Kerstin Spiekermann, Noelle Paulson, Katharina Haake, Philippe Block with support of Eva Schnewly, Rolf Imseng

Sponsors

NCCR Digital Fabrication, ETH Zurich, DeBrunner Acifer, Doka Switzerland and Italy, Jakob Rope Systems, NOWN, Symme3D

Documentation and Video

Footage: Thom de Bie, Mariana Popescu, Lotter Scheder-Bieschin, Achilleas Xydis, Serban Bodea

Editing: Thom De Bie

Animations: Lotte Scheder-Bieschin, Michele Capelli