KnitCrete

2015 Digital Fabrication KnitCrete Research ZurichKnitCrete

KnitCrete is a novel, material-saving, labour-reducing and cost-effective formwork system for the casting of doubly curved geometries in concrete. The KnitCrete technology is being developed at ETH Zurich by the Block Research Group in collaboration with the Chair for Physical Chemistry of Building Materials, as part of the Swiss National Centre of Competence in Research (NCCR) in Digital Fabrication.

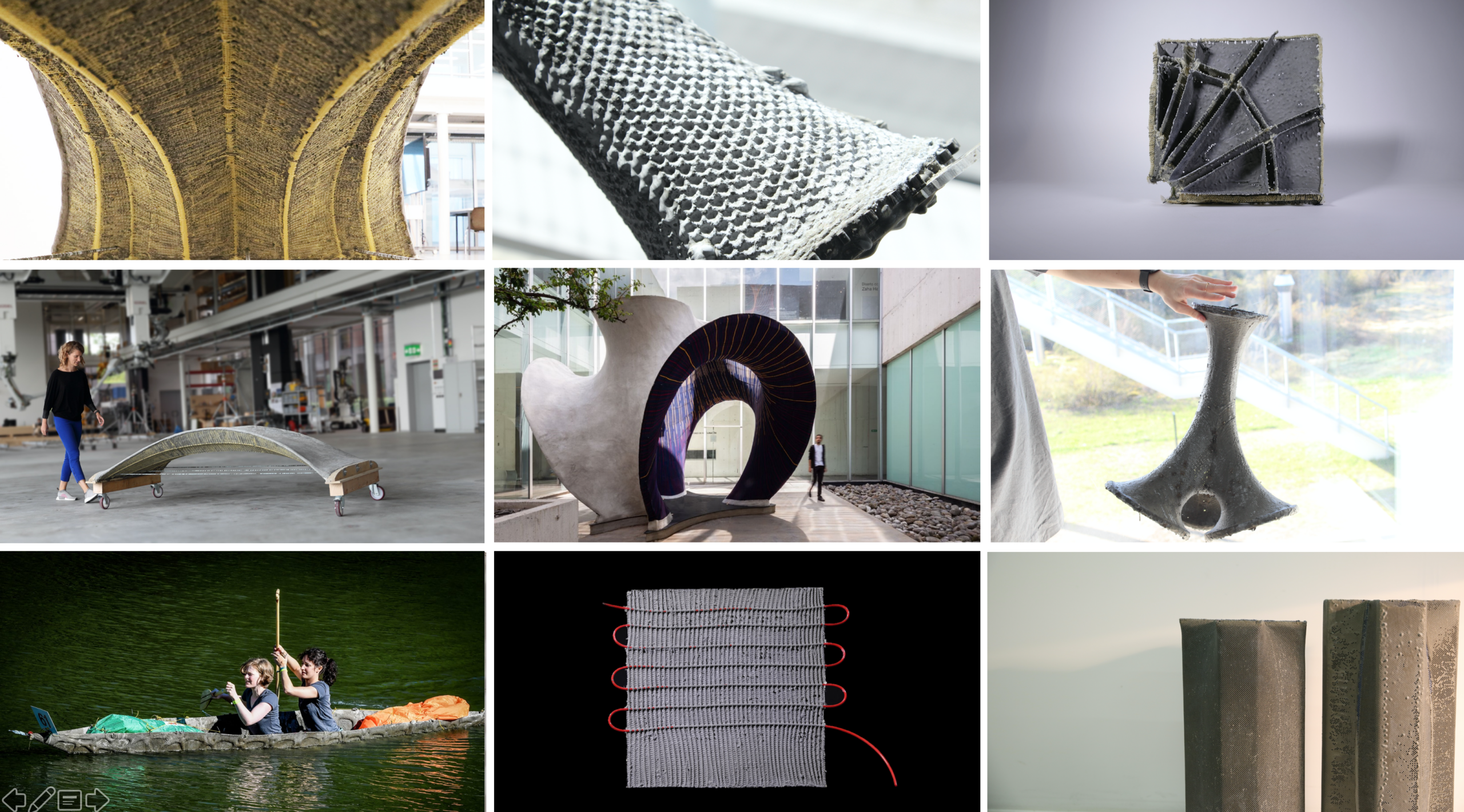

KnitCrete formworks use a custom, 3D-knitted, technical textile as a lightweight, stay-in-place shuttering, coated with a special cement paste to create a rigid mould, and supported by additional falsework elements such as a tensioned cable-net or bending-active splines. Compared to conventional weaving, knitting minimises the need for cutting patterns to create spatial surfaces, allows for the directional variation of material properties, and simplifies the integration of channels and openings, for example, for the insertion of additional formwork elements, insulation, reinforcements, electrical components and technical systems for heating and cooling.

The hybrid and ultra-lightweight KnitCrete formworks are thus easily transportable, reduce the need for additional supporting structure and scaffolding, and simplify the logistics on the construction site.

More Information

Concrete is one of the predominant building materials in construction. This applies not only to standard construction but especially to complex architectural shapes. Reinforced concrete lends itself well to such geometries since concrete can take on almost any desired shape when given a formwork. This formal flexibility makes it an attractive building material, but such flexibility comes at a cost, namely, the needed formwork to cast it upon. Currently, prefabrication is an optimised process that relies on standardisation and serialisation linked to the reusability of the formwork needed for casting. For bespoke geometries, the formwork can usually not be reused. These one-off products often account for a large percentage of the total building cost. Furthermore, much of the time spent on design and manufacturing shifts to the production of the complex formwork. This is a problem both in terms of cost and sustainability. Additionally, nonstandard reinforcement strategies have to be developed both for the formwork and the reinforcement of the structure itself.

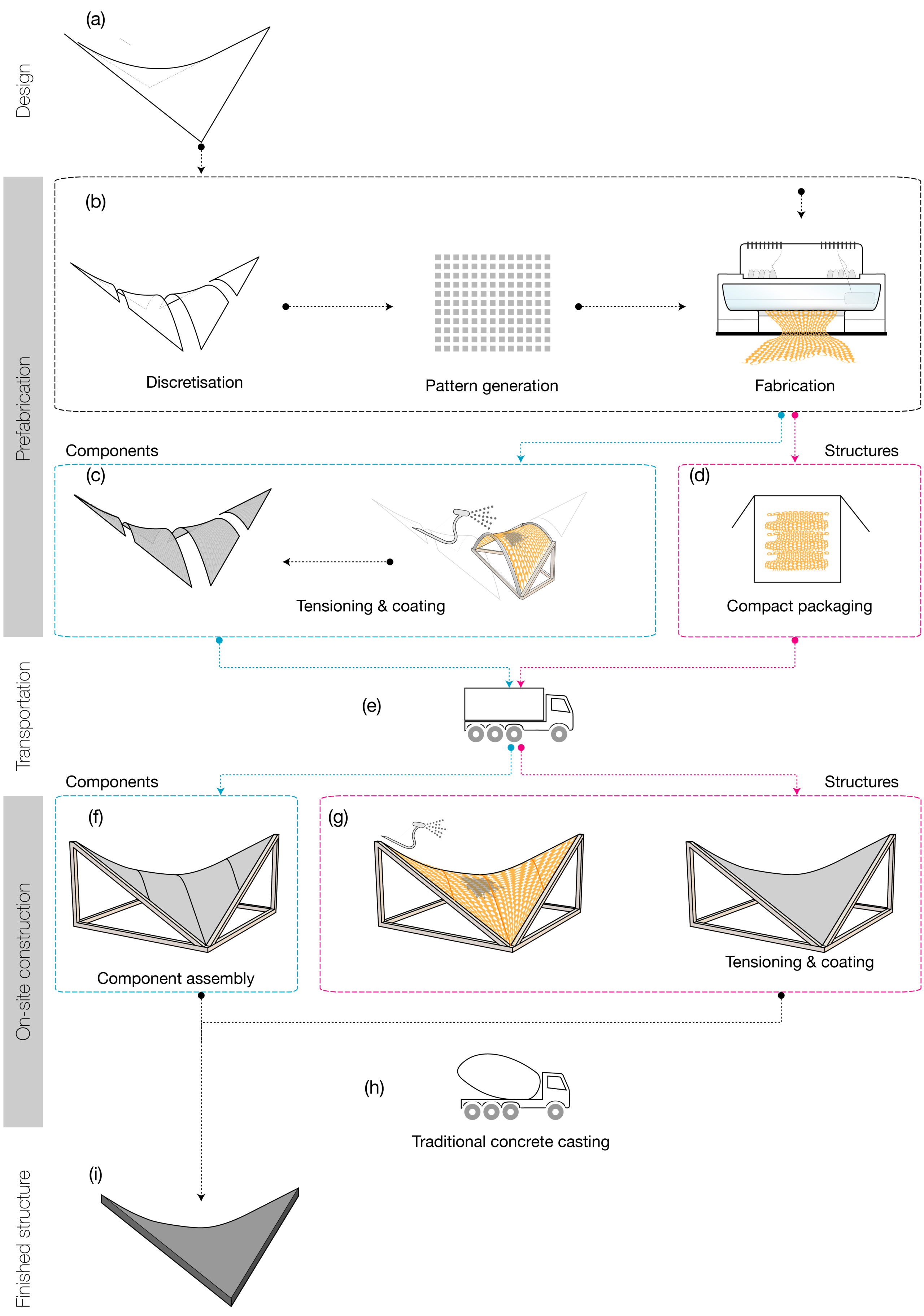

This research focuses on those complex, bespoke geometries that need custom formwork with integrated solutions for the reinforcements. It develops a prefabricated, spatial, textile formwork system that:

- is easy to transport and handle

- acts as stay-in-place formwork

- includes guiding features for reinforcements

- has accurate placement of material

The approach combines 3D-knitted technical textiles with special cement paste coatings to create a lightweight stay-in-place formwork for concrete. This combination promises to provide a material-saving, labour-reducing and cost-effective solution for the construction of complex concrete structures. Customised textiles informed by structural considerations, among other parameters, can be easily fabricated and used with great geometrical freedom.

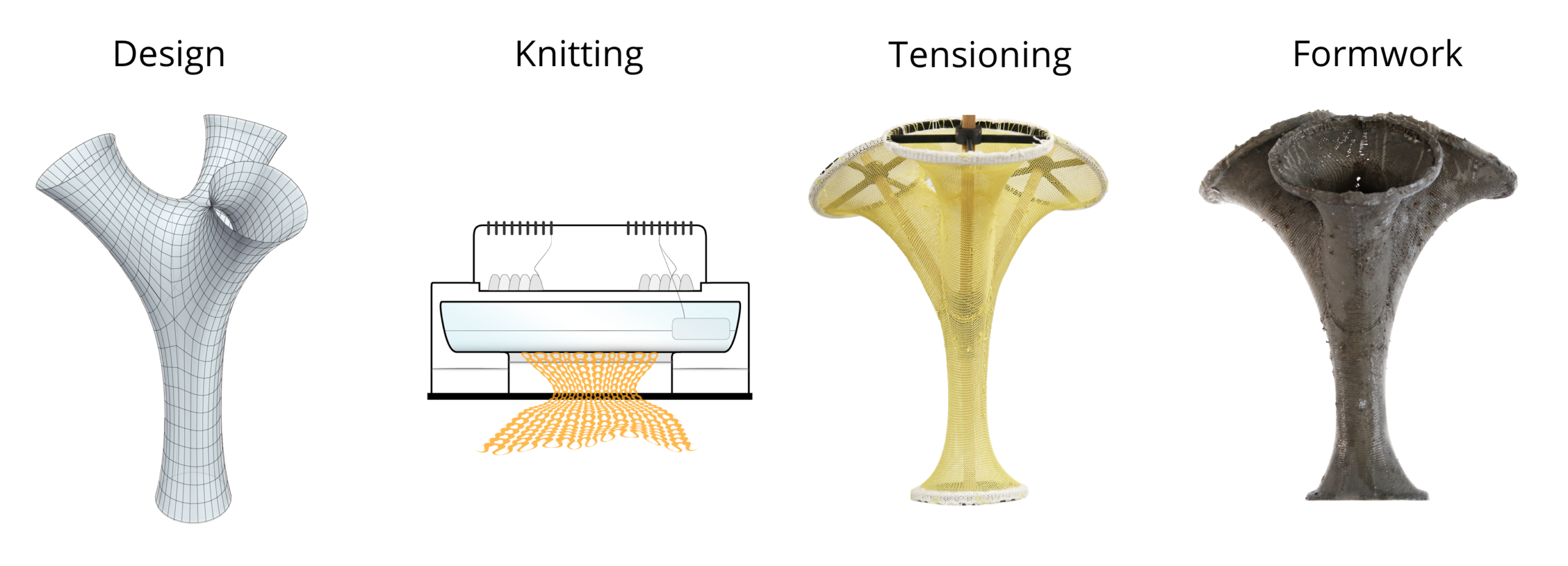

First, a custom knit pattern is algorithmically generated based on the desired 3D geometry. This pattern is then produced using an industrial knitting machine. The textile is tensioned into the desired shape, which can be done using rigid elements as an external frame or as part of the textile or flexible elements such as bending-active structures. After tensioning, a thin cement paste coating is applied. To obtain a low tensioning of the textile and also minimise deformations during casting without intermediate support from below, strength is built up by gradually applying thin layers of concrete. This package can now be used as formwork for casting concrete in a traditional fashion.

This textile-concrete hybrid results in an ultra-lightweight formwork that is easily transportable and significantly reduces the need for falsework, support and scaffolding, which also has many advantages on the construction site.

Related Publications

Popescu M., Rippmann M., Liew A., Reiter L., Flatt R.J., Van Mele T. and Block P. “Structural design, digital fabrication and construction of the cable-net and knitted formwork of the KnitCandela concrete shell”, Structures, 2020. In press

Popescu M., Rippmann M., Van Mele T. and Block P. “KnitCandela – Challenging the construction, logistics, waste and economy of concrete-shell formworks”, FABRICATE 2020, London, 2020 (April).

Popescu M., Reiter L., Liew A., Van Mele T., Flatt R.J. and Block P. “Building in concrete with a knitted stay-in-place formwork: Prototype of a concrete shell bridge”, Structures, 14: 322-332, 2018

Popescu M., Rippmann M., Van Mele T. and Block P. “Complex Concrete casting: Knitting stay-in-place fabric formwork”, Proceedings of the IASS Symposium, Tokyo 2016 (September).

Selected Projects

Credits

Team (PhD research)

Mariana Popescu

Supervisor

Philippe Block – BRG, ETH Zurich

Collaborators

Lex Reiter, Robert J. Flatt – PCBM, ETH Zurich

Quentin Bollengier, Chokri Cherif – ITM, TU Dresden

Supported by

Tom Van Mele, Matthias Rippmann, Andrew Liew – BRG, ETH Zurich

NCCR Digital Fabrication