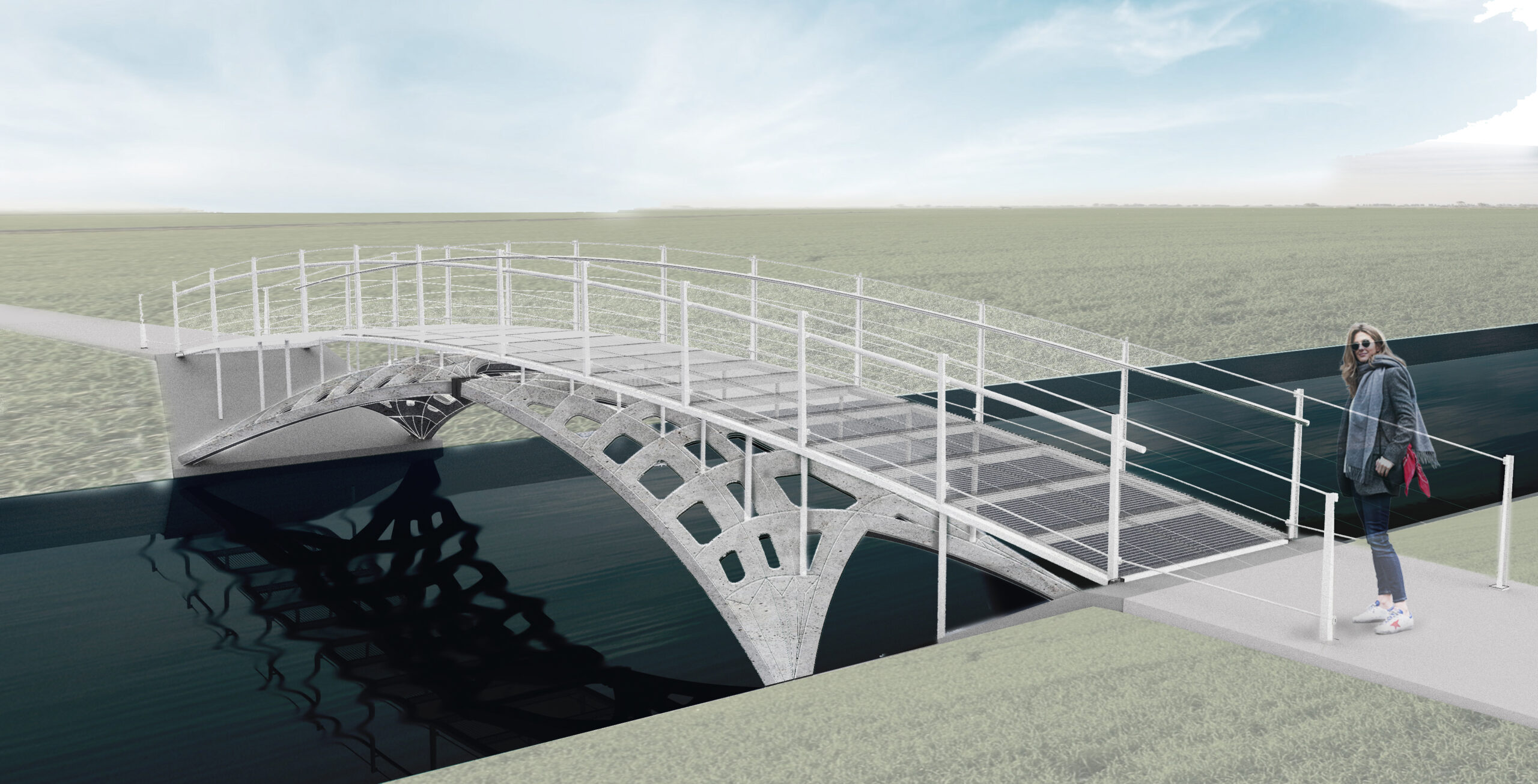

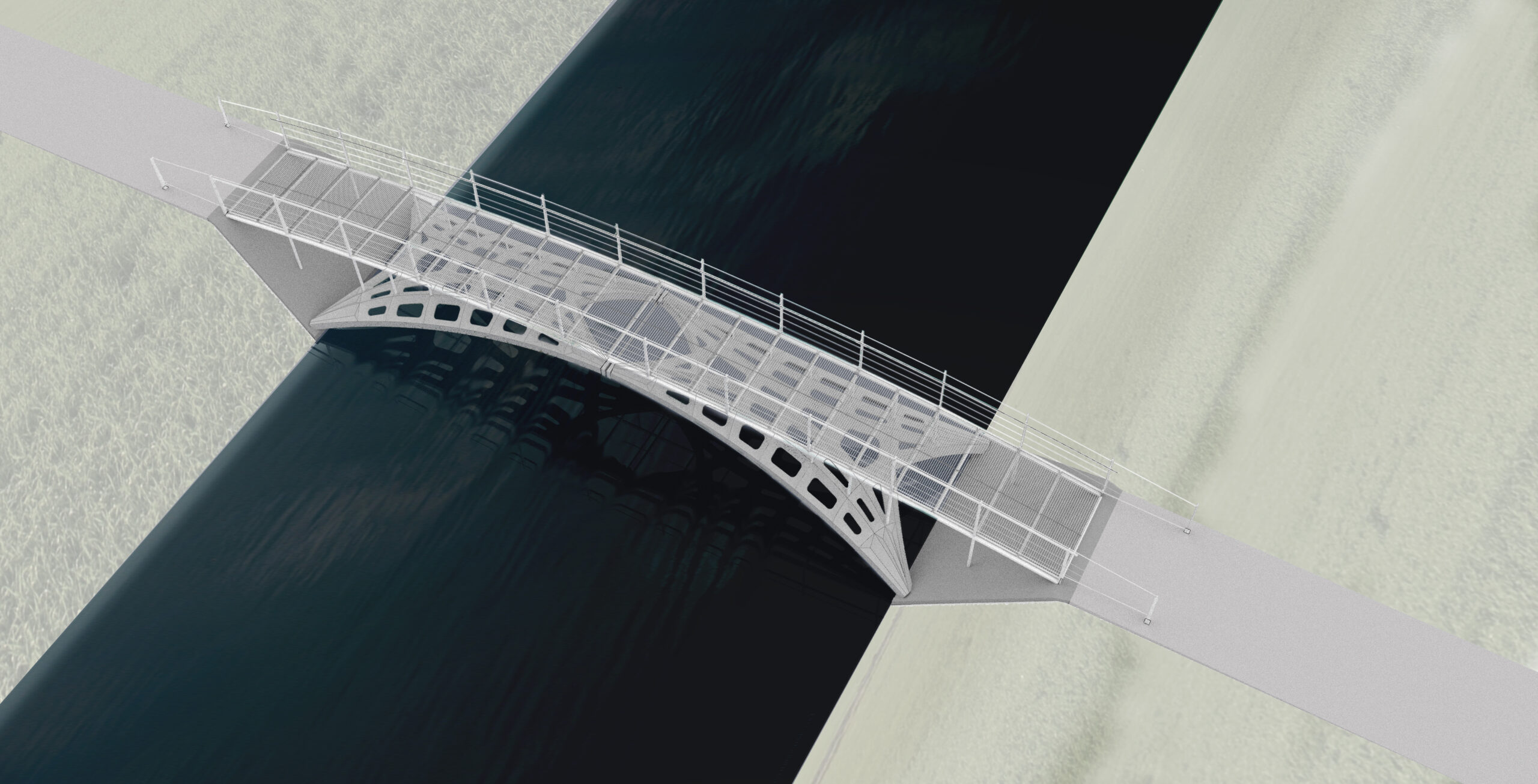

Groene Boog Footbridge

2021 Design Digital Fabrication KnitCrete Research Rotterdam sustainabilityThis circular bridge’s design and fabrication process are developed collaboratively by the Block Research Group at ETH Zurich and De Groene Boog, commissioned by the Dutch Ministry of Infrastructure and Water Management (Rijkswaterstaat).

The need for sustainable design, engineering and fabrication strategies for concrete construction is recognised as a key challenge in the building industry. Using principles of structural geometry and material effectiveness in design makes it possible to significantly reduce the amount of material used in a structure and its embodied emissions.

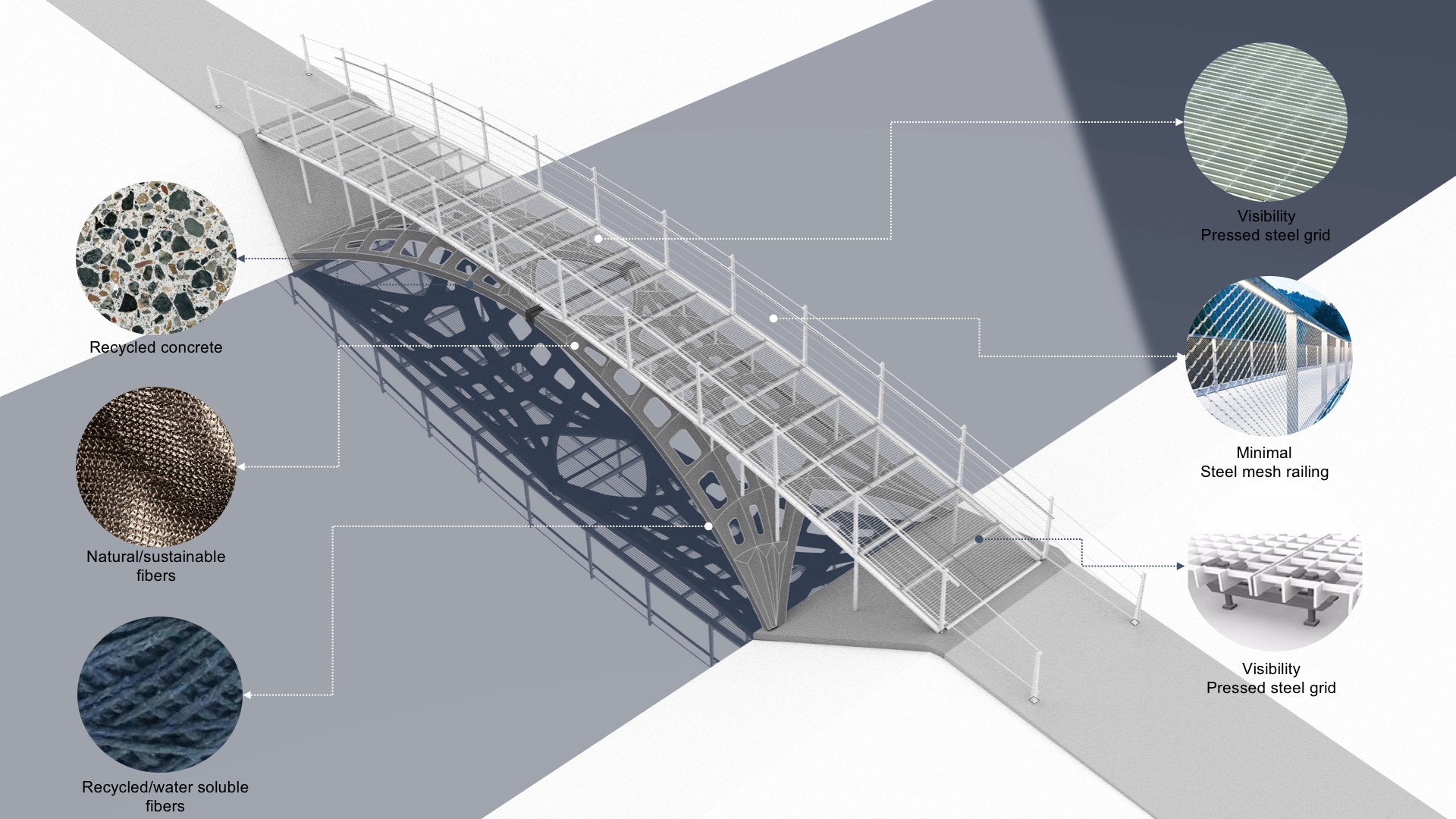

This project presents the design, engineering and digital fabrication strategies for a circular pedestrian bridge to be built as part of “De Groene Boog” development of the A16 highway north of Rotterdam, The Netherlands. The bridge is designed as a lightweight funicular concrete shell based on the principle of a three-hinge arch extrapolated to 3D geometry. In its realisation, it demonstrates a model of circular construction using novel material developments (such as recycled concrete) and an efficient flexible formwork system. A hybrid spline-supported 3D-knitted textile made of recycled and natural fibres that is easy and fast to assemble will be the formwork to cast the complex structural geometry needing minimal scaffolding. An in-house developed computational pipeline, based on the open-source COMPAS framework, enables the efficient design, collaborative exchange and streamlined fabrication of the bridge.

Credits

Client

Rijkswaterstaat

Structural Design and Engineering

Block Research Group, ETH Zurich: Sam Bouten, Mariana Popescu, Tom Van Mele, Philippe Block

Engineer of record and foundations

BESIX Engineering / De Groene Boog: Kenneth Wyns, Pierre Mengeot, Michiel Dhont

Formwork innovation and fabrication

Block Research Group, ETH Zurich: Mariana Popescu, Sam Bouten, Tom Van Mele, Philippe Block

Contractor

De Groene Boog